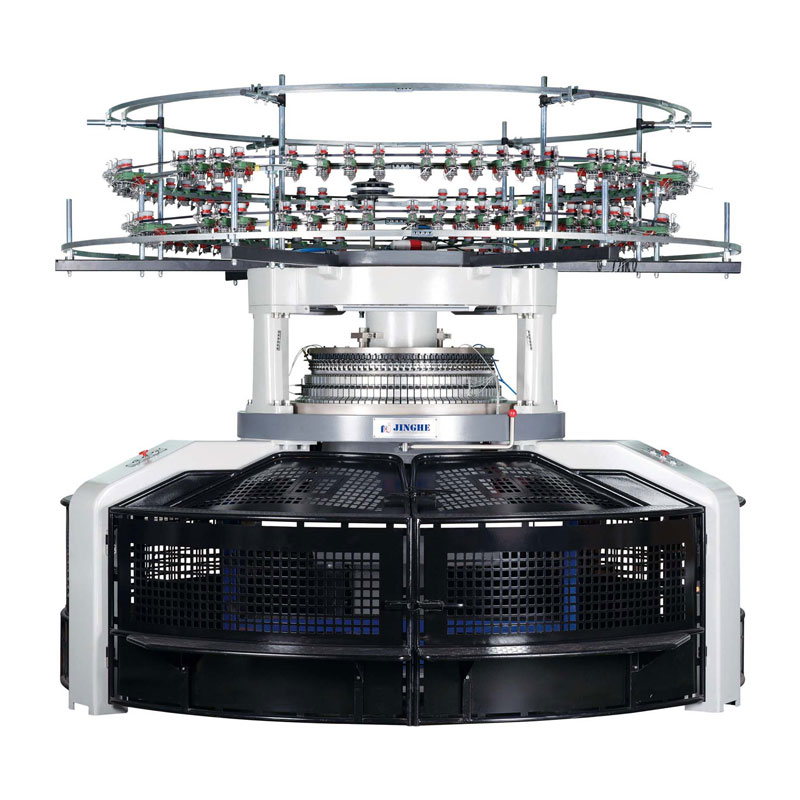

12-40 Gauge Double Open Width Circular Knitting Machine

- Informació

- Vídeo

High Speed Circular Knitting Machine

Product description:

● 1.The cylinder seat is to prevent the bottom of the machine from spilling oil on the fabric. Both the large plate and the yarn feeder transmission gear box adopt oil-immersed design, which improves the stability, reduces noise and the influence of the fabric due to braking. The new large plate and large plate gear system can better support the long-term load impact of high tension and high load.

● 2.Powerful air dust fan and rotating nozzle can further enhance the dusting effect. Cam base can reduce batt accumulation. We have solved the problems that may occur under high-speed production for customers in advance。

● 3.The machine with 4 track production ordinary plain fabric and organization fabric, which are used in sports fabrics and casual clothing. Besides . from thick gauges to fine gauges; from small diameters to big diameters; from common fabric to bedding fabric ; from high-volume single yarn weaving to multi-spraying .and that can be equipped with open-width system and high-rolling frame . All of the above can be produced by this model to satisfy the various needs of different customers

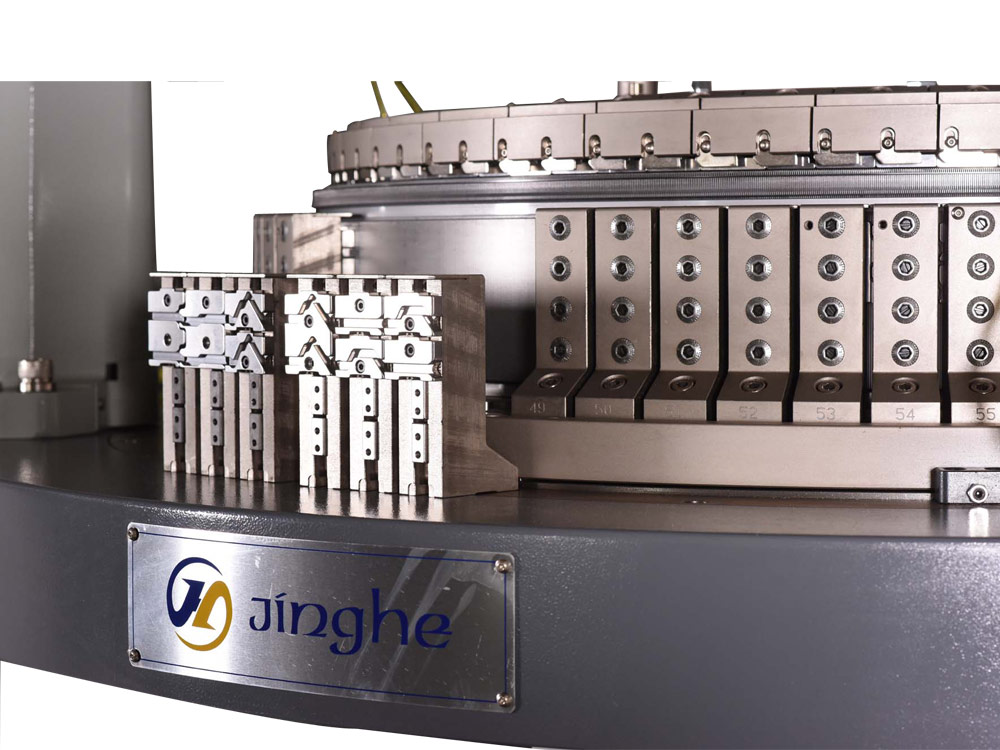

Circualr knitting machine Heart of Circular knitting machine

CNC machinging center Digital controlled lathe

With the vigorous development of the fashion industry, the demand for innovative technologies that can improve production efficiency and quality in the textile industry is becoming increasingly urgent. In recent years, the 12-40 size double opening circular knitting machine has become the focus of attention for many fashion brands and manufacturers due to its groundbreaking design and functions. So, what is a 12-40 size double opening circular knitting machine? What revolutionary features does it have?

The 12-40 size double opening circular knitting machine is an innovative knitting equipment that adopts a double opening design, which has a wider range of applications and higher production efficiency compared to traditional knitting machines. This means that the equipment can simultaneously produce two different patterns of fabrics, greatly improving the production capacity and flexibility of the production line.

High efficiency is one of the important characteristics of the 12-40 size double opening circular knitting machine. With advanced automation technology and precise mechanical structure, this equipment can quickly and accurately complete complex operations such as opening, slitting, and color matching, greatly improving production efficiency. Compared with traditional single width knitting machines, the double opening design allows the production line to produce two different patterns of fabrics simultaneously during each operation, effectively reducing production cycle and time costs.

In addition to high efficiency, the 12-40 size double opening circular knitting machine also has excellent quality control capabilities. Through precise control systems and intelligent detection devices, this device can monitor and adjust key indicators such as density, tightness, and color of fabrics in real-time, ensuring the stability and consistency of product quality. This is particularly important for the fashion industry, as high-quality fabrics are the foundation for building high-end fashion brands.

However, the introduction of 12-40 specification double opening circular knitting machines also faces some challenges. Firstly, the price of this type of equipment is usually higher and may require higher investment for small manufacturers. Secondly, operators need to receive professional training to master the proficient operating skills of the equipment, ensure its normal operation and maximize its potential.

Despite facing some challenges, the revolutionary breakthrough of the 12-40 specification double opening circular knitting machine has attracted widespread attention from the fashion industry. Many well-known brands and manufacturers have actively adopted this equipment, achieving significant production efficiency and competitive advantage. It can be foreseen that the 12-40 specification double opening circular knitting machine will become a new trend in the fashion industry, promoting the transformation of the fashion industry towards more efficient and flexible production methods.

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 25 | 52F-84F | 12G-40G | 18-40R.P.M |

| 25 | 60F-106F | 12G-40G | 18-40R.P.M |

| 30 | 96F-108F | 12G-32G | 18-40R.P.M |

| 25 | 70F-122F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Assembly workshop Cylinder workshop

CNC maching center Shipping goods

Certificate:

Contact us:

![]() QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

QuanZhou JingHe YuanWei Knitting Machinery Co.LTd

Add: Inside Honglei Stone Factory,Liaocuoqian,Luoyang Town, Hui'an County, Quanzhou City, Fujian Province, China

Phone/Whatsapp:+8613506078504

Website:https://www.jhknitmachinery.com/

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.