Mataas na Kalidad na Propesyonal na Circular Knitting Machine

- Informació

- Vídeo

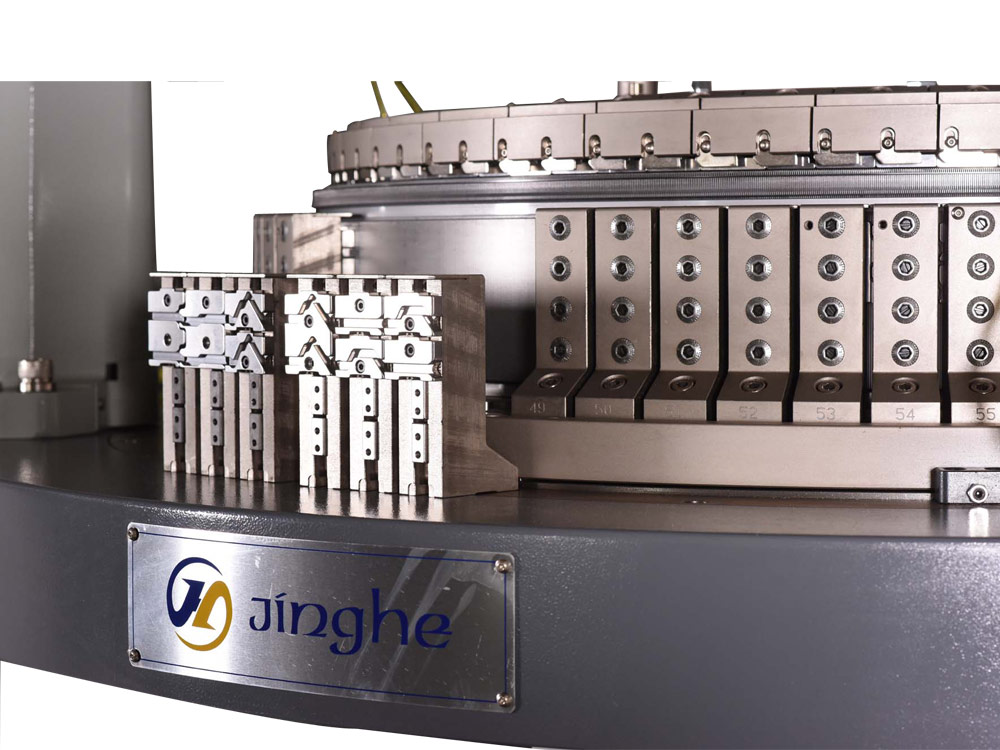

High Qualtiy Professional Circular Knitting Machine

Product description:

Choosing the right circular knitting machine for your business needs can be a daunting task, but there are a few factors to consider that can help you make an informed decision:

Gauge: The gauge of a circular knitting machine refers to the number of needles per inch. The gauge you choose will depend on the type of fabric you want to produce. For example, a smaller gauge is suitable for producing fine fabrics like silk, while a larger gauge is better for producing heavier fabrics like wool.

Diameter: The diameter of a circular knitting machine refers to the size of the cylinder. The diameter you choose will depend on the size of the fabric you want to produce. For example, a smaller diameter is suitable for producing small items like socks, while a larger diameter is better for producing larger items like blankets.

Number of Feeders: The number of feeders on a circular knitting machine refers to the number of yarns that can be used at once. The number of feeders you choose will depend on the complexity of the fabric you want to produce. For example, a machine with more feeders is suitable for producing fabrics with multiple colors or textures.

Brand and Quality: It is important to choose a reputable brand and high-quality machine to ensure reliability and longevity. Research different brands and read reviews from other users to find the best option for your business needs.

By considering these factors, you can choose the right circular knitting machine for your business needs and produce high-quality fabrics efficiently.

High quality professional circular knitting machine is a high-performance and precision controlled knitting machine used to produce various high-quality and professional level knitted products. This type of machine usually adopts advanced technology and processes, with higher weaving speed, more precise weaving control, and more diverse weaving functions.

The characteristics and advantages of high-quality professional circular knitting machines include:

High speed weaving ability: This type of machine usually has a high weaving speed, which can quickly complete large-scale production tasks and improve production efficiency.

Precision weaving control: The advanced control system built into the machine can achieve precise needle bed movement and needle blade operation, thereby producing high-quality and detailed knitwear.

Diversified knitting functions: High quality professional circular knitting machines are usually equipped with multiple knitting heads and methods, which can flexibly switch between different knitting effects and designs to meet the needs of different products.

Durable and stable machine structure: This type of machine usually adopts a sturdy and durable structural design and high-quality components, which can operate stably for a long time and reduce the frequency of faults and maintenance.

Highly automated and intelligent: High quality professional circular knitting machines are equipped with advanced automation devices and intelligent control systems, which can achieve automated weaving operations and intelligent production management, improve work efficiency and production consistency.

When purchasing high-quality professional circular knitting machines, the following factors need to be considered:

1.Product requirements: Select suitable machine models and specifications based on the type and specifications of knitted products that need to be produced.

2.Technical requirements: Considering the required weaving speed, accuracy of the weaving control system, and diversity of weaving functions.

3.Reliability and stability: Choose reliable machine structures and durable components to ensure long-term stable operation and low failure rates.

4.After sales service and support: Choose a supplier with good after-sales service and technical support to receive timely repair and support during use.

High quality professional circular knitting machines are widely used in fields such as fashion, textiles, and sportswear, meeting the production needs of high quality and performance requirements for knitted goods.

Technical Data

| Diameter | Feeders | Gauge | RPM |

| 25 | 52F-84F | 12G-40G | 18-40R.P.M |

| 25 | 60F-106F | 12G-40G | 18-40R.P.M |

| 30 | 86F-108F | 12G-32G | 18-40R.P.M |

| 25 | 70F-122F | 12G-32G | 18-40R.P.M |

Packing&Delivery

Packing:

Wooden box package is our standard & recommended packing, and the machine will be in sealed status. If export to european countries,the wooden material will be fumigated. For remoted countries, we suggest to use vacuum package.

Delivery time:

Basic Machine:30-35days

Jacquard Machine:45-50days

Cusomized Machine: 50days or More(depends on different situations)

Payment: TT or L/C is acceptable

Certificate:

Company Profile:

QuanZhou JingHe Circular Knitting Machinery Co.,LTD is the leading supplier of Circular Knitting machine, mainly produce Single Jersey Circular knitting machine, Double Jersey circular knitting machine,Jacquard Circular knitting machine.

Flexible customization and innovation, Strictly inspect each process of the product in the production process. Quality-oriented is the production philosophy of our factory, we strictly require that every process reach high standard. Therefore , a small screw must be layer of screened to ensure that each one must be bester

Advanced and intelligent production equipment and scientific management mode ensure that every detail from zero to the whole can be tracked in place. We have even established a complete service system for our customers, so that every customer is assured of our products and satisfied with our pre-sales and after-sales.

After Sale Service

Application Area: Vest, T-shirt, Polo shirts, functional sportswear and underwear or seamless clothes(small size).

Applicable Yarn Materials: cotton, synthetic fiber, silk, artifical wool, mesh or elastic cloth.

FAQ:

Q : Where are your factory locates?

A : Our factory is located in QuanZhou city, FUJIAN province.

Q : Are all the main spare parts of the machine are produced by your factory?

A : Yes, all the main spare parts are produced by our factory with the most advanced processing.

Q : Will your machine be tested and adjusted before the machine delivery?

A : Yes, we will test and adjust the machine before delivery, also if the customer has special fabric demand, we can knit and test it in the machine before machine delivery

Q : Do you have after-sales service?

A : Yes, We have excellent after-sales service, can give a quick response, support in Chinese, English, Video

support is available.

Q :How long is the warranty period of the product?

A : We offer a warranty for about one year after customer received products.(Except for man-made damage)

Q : What are the main applications for the fabrics produced by your machines?

A : Fabrics knitted by our machines mainly can be used for Garments, Home textile ( like bedding sheet, mattress fabric, carpet), Sports fabric ( like Yoga fabric, diving fabric, sportswear ), Also for the jacquard machine, the pattern is easy to make by computer without limitation so the fabric can be widely used.